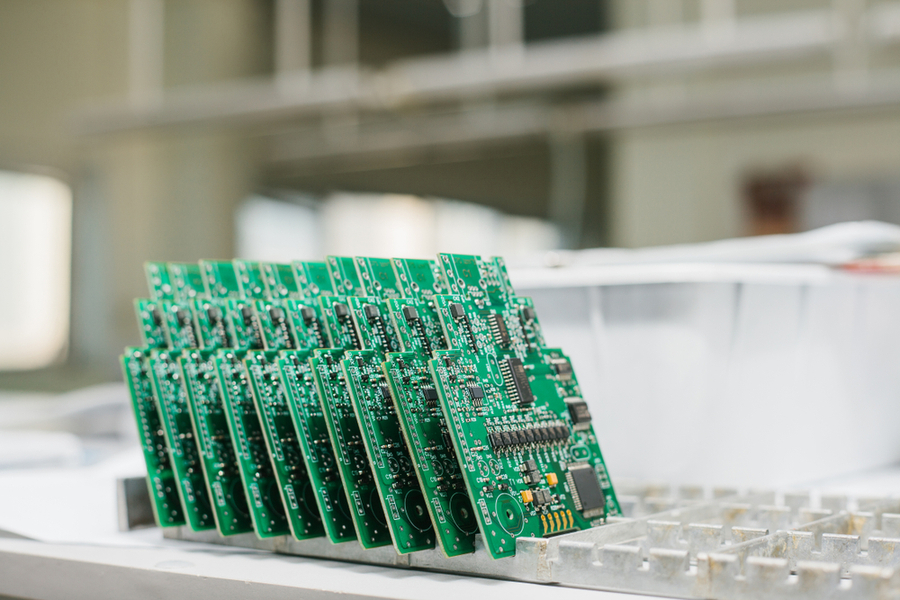

Make sure your design works before buying a large batch of printed circuit boards. To accomplish this objective in a quick and premium manner, you will first need to construct a model of your board. This prototype will be a trial run of your design, and its functioning will be evaluated. On the other hand, you don’t want to squander time on a drawn-out process of prototyping. Because of this, you should collaborate with a PCB manufacturer such as Chainapcbone, which can supply you with correct prototypes promptly and at an affordable price. As soon as you are pleased with the prototypes, they can finish your production line run using the same dedication to quality and efficiency. You may further improve the efficiency of your prototype process by being familiar with its components. This will allow you to anticipate any challenges that may arise and give the essential information promptly. So, what exactly is involved in PCB prototyping? Keep reading to learn more about it.

The Benefits of Using PCB Prototyping

Advantages of Creating a PCB Prototype Before placing a purchase order for a complete production batch of a newly designed printed circuit board (PCB), it is advised that you first develop a prototype. They make certain that their concept PCB service is both speedy and user-friendly so that you may test the board without experiencing any delays or complications. The following are some of the things that PCB prototyping enables you to do:

- Identify potential problems with the product’s design at an early stage in the manufacturing process, well before you commit substantial financial resources.

- Test various designs affordably

- Obtain a precise illustration of how your board will perform its functions.

Ensure that the procedure of creating the PCB prototype is suitable for your requirements before beginning the process. Even if it is helpful for a lot of different tasks, having it is not necessary. If you want to construct a prototype, you will need some fundamental information regarding the project before you can get started.

PCB Prototypes are an excellent tool for validating the design of your board or conducting quality assurance tests on it. Whenever a fresh design is utilized for a new project, the utilization of a prototype is strongly recommended. If you have already manufactured an electronic product using that board without any problems, you probably do not need to create a prototype. You should, however, place an order for a prototype before making any modifications to the design or before creating an entirely new Circuit design or product. Through the use of their fast prototyping service, they can construct test boards with a maximum of 8 layers, as well as deliver boards with quality level IPC1 and utilizing standard RF-4 material. They have a construction period of four to five business days and can fulfill orders ranging from five to one hundred units for prototypes.

When you collaborate with Chainapcbone, you can shorten the amount of time required to construct a prototype while simultaneously improving its quality and precision. Your concept may be prototyped in 3–7 days. Prototype purchases of five parts save money. Identifying design defects and other concerns at an earlier stage in the production process, will, of course, help you save money. If you have any inquiries regarding PCB prototyping, do not hesitate to get in touch with their helpful customer support team. They can assist in the prototype and manufacturing phases, guaranteeing that the outcomes you seek are achieved.

ChinaPCBOne Technology LTD. is the author of this article on pcb assembly. Find more information, about PCB prototype.