Today technology is advancing faster, and several gadgets have been upgraded from the past. If you keep an outdated or obsolete electronic gadget with yourself, it will be difficult to fix the part once it becomes defective. If your device requires a new component, it will be difficult for you to change the defective parts and find a spare part. Therefore you need to throw your device and buy a new model, which will be expensive. However, you can avoid such circumstances by hiring the best and most highly effective PCB assembly service. When you hire a PCB assembly service, you need not spend too much on getting new models or gadgets. The best feature about PCB assembly services is that you need not spend much money on buying new models. With a PCB assembly service, you can easily update your existing model at a much cheaper rate.

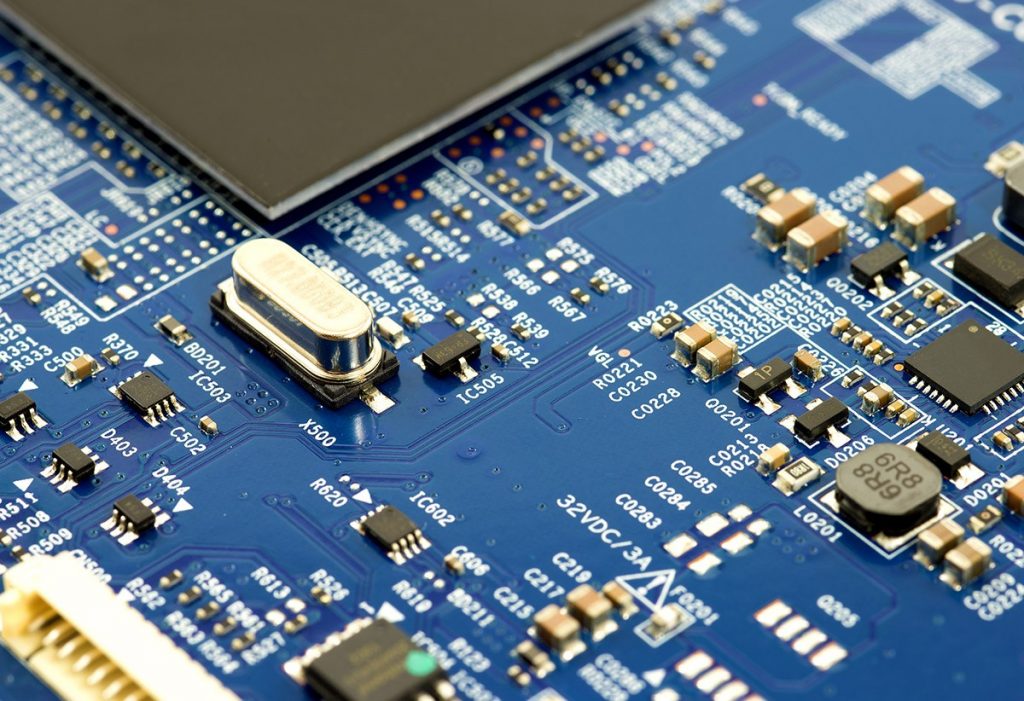

Printed Circuit Board Assembly Technology

Assembly services have been in great popularity right from their inception of the services. This is why they are the most common and renowned services. Companies look for the best and most highly effective assembling technology, manufacturer, and services to offer their customers the best service.

Attaching electrical components to a PCB is known as printed circuit assembly. Printed circuit assembly can be started only when the circuit board assembly is created entirely. There are different kinds of techniques that are used for attaching electronic parts to the printed circuit board. Hole technology and surface mount technology are the 2 techniques that are combined and used on single printed circuit assembly. Printed circuit assembly helps support and connect the electronic components and paths mechanically, and this can be achieved using conductive traces or pathways engraved from laminated copper sheers on non-conductive substrates.

3 ways for creating PCB assembly are as follows

- Surface mount assembly –

Surface mount assembly technology is one of the widely used ways to create PCB assembly. In this type of technology, components and parts consist of metal tabs so they can be soldered smoothly to the PCB board. It is easy to achieve high circuit density if the parts are attached on both sides of the PCB circuit

- Conventional PTH Assembly –

PTH assembly stands for plated through hole technology which comes with components and parts that are attached which lead. Components get inserted into the circuit board with the help of drilled holes, and this technique can be expensive; however, it will lead to the manufacture of the most efficient and effective PCB board.

- Box-build, Electro-Mechanical Assembly –

This assembly technology includes wire, harness, custom metal work, cable assembly, molded plastic, and looms fault manufacturing circuit board assembly.

No matter how robust and effective PCB assembly design is, it is quite prone to the standard warranty. As outdated or damaged PCB manufacturing assembly is not accessible in the market so easily, it becomes necessary to hire circuit board assembly services. PCB manufacturers must offer their clients efficient and effective printed circuit assembly services. In this way, customers can be satisfied and will be able to trust the manufacturer. Printed circuit board assembly is quite reliable in the manufacturing industry as it provides customers with highly effective printed circuit assembly services.